MANUFACTURING

Achieve More with Modern Manufacturing

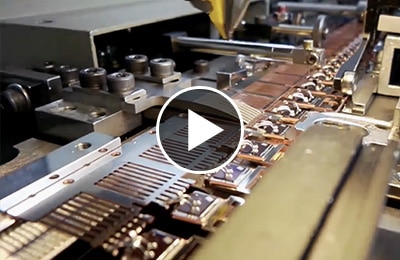

Manufacturers rely on manufacturing management software to manage processes and

streamline the production cycle as part of an entire supply chain management (SCM)

system. You must integrate all kinds of hardware robots, vision systems, motors,

conveyors, sensors and much more.

You can’t compete in the twenty-first century using yesterday’s systems. In the digital

age, your manufacturing systems need to do more. To stay ahead of evolving consumer

demands, you need to continuously innovate. You can no longer afford to have

manufacturing processes and information in silos. You need to be leaner and more

competitive.

The quality of your product determines how well you fare in an ever increasingly

competitive market where buyers have instant access to social media and customer

feedback. You need a quality process that checks all critical control points.

RCO works with all the top tier hardware and software vendors to provide you the best

of breed solutions. With over 30 years of system integration and custom hardware and

software systems for manufacturing we have the experience to make the system work.

The quality of your product determines how well you fare in an ever increasingly

competitive market where buyers have instant access to social media and customer

feedback. You need a quality process that checks all critical control points.

RCO works with all the top tier hardware and software vendors to provide you the best

of breed solutions. With over 30 years of system integration and custom hardware and

software systems for manufacturing we have the experience to make the system work.

Control Stations

RCO designs and builds control stations no matter where you manufacture product. Every station can run stand alone and automatically synchronize information to a centralized ERP. You have complete visibility and control from any web browser or mobile device. You get full schematics, design documents and software source code so your maintenance staff can handle any emergency right away.

We already have hundreds of controllers like Allen Bradley, Siemens, Schneider, Omron, Automation Direct can we retrofit these and get these connected?

YES 100%

RCO has designed special modules that will connect your systems to the web. You can run on premise or run in the cloud.

What about service since we have factories all over the world in some remote locations

and we operate 24x7x365?

RCO Services customers anywhere in the world any time day or night. When you run a

production line and you have a problem you want to reach somebody and get the

problem resolved as fast as possible and we have been doing this for years. Part of the

installation process is training the maintenance staff to handle problems and providing

enough spares for them to service equipment.

Weights

Collect weight measurements at any point in your manufacturing process and integrate this with your supply chain management system. Weight is a fundamental measurement that you need to monitor all the way through the system especially at the shipping department.

Conveyor Weights

Forklift Weights

Truck Scale Weights

Hand Pallet Weights

Manufacturing in the Cloud

Moving your manufacturing systems to the cloud brings a whole new level of

agility to your manufacturing, planning, and fulfillment processes. Oracle

Manufacturing Cloud enables you to transform your business for the digital

age—without the expensive overhead costs. Instead of investing in IT

infrastructure, Oracle Manufacturing Cloud meets your evolving needs to

scale as your business grows.

For a significantly lower cost of ownership, you gain visibility across your

entire supply chain. Leverage new capabilities for business analytics, mobile,

and social to build a highly efficient supply network that spans your extended

enterprise of employees, customers, and business partners.

Oracle Manufacturing Cloud is an end-to-end, integrated solution that enables you to innovative faster, increase productivity, and lower costs.

- Gain complete visibility into plant operations

- Collect and analyze real-time performance data to optimize productivity and maximize profit margins

- Streamline your entire production cycle and manage operations more efficiently

- Align manufacturing with your value chain and create integrated production plans and schedules

- Empower your shop floor workers with greater visibility across the entire production line—in real-time

- Inform your value chain with advanced analytics and role-based dashboards

- Standardize your global manufacturing networks with quality compliance processes

Quality Control

RCO provides the latest mobile and stationary control systems to provide food manufacturers an accurate and reliable system to meet FDA and FSMA standards for record keeping and assist in achieving a superior quality control system.

- Automatic Data Collection

- Mobile Forms (PDF)

- GIS Mapping

- Control Systems Alarm and Event Monitoring

- Barcoding and RFID

- Imaging

Sensors

You can measure any aspect of your supply line from incoming weights to using the latest barcoding and imaging cameras. We support hundreds of different sensors (4- 20ma and pulse modulated). We measure tank heights, temperature, pressure, flow, vibration, speed just to name a few.

800-972-3027

800-972-3027