Products

ELD

A fully certified FMCSA ELD to help your drivers stay in compliance at all times.

Extra features include the ability to have electronic forms of your medical records and skill performance evaluations and your daily vehicle inspection reports.

Satellite Tracker

Your customers can track where their product is on their mobile device or on a browser.

See every trailer on a map on your phone, workstation or tablet anytime. You can see the trail where the trailer went from any time period.

Cellular Tracker

Your customers can track where their product is on their mobile device or on a browser.

See every trailer on a map on your phone, workstation or tablet anytime. You can see the trail where the trailer went from any time period.

Dashcams

Truck drivers are at fault in 44% of two-vehicle crashes involving trucks, as reported by the Federal Motor Carrier Safety Administration (FMCSA).

A dashcam is only as good as its ability to capture crucial details-usually license plate number. The 8-megapixel 4K UHD sensor does just that by capturing 4 times as many pixels as in Full HD.

Temperature

Real time sensor telematics enables you to provide customers with complete cold chain accountability for your reefers.

The temperature and humidity can have separate high low values. With the door sensor you have complete reporting on when trailers are loaded and unloaded.

Vision

Convenience features are designed to assist you with the most burdensome parts of driving.

Improves existing functionality to make your car safer and more capable over time.

Inventory

The concept of inventory, stock or work in process has been extended from manufacturing systems to service businesses and projects.

Inventory or stock refers to the goods and materials that a business holds for the ultimate goal of resale, production or utilisation. Inventory management is a discipline primarily about specifying the shape and placement of stocked goods.

Fuel Level Sensor

Allows measuring current fuel volume in a fuel tank

Wireless sensor allows measuring current fuel volume and its changes in a fuel tank. Is used as a part of vehicle telematics system (GPS vehicle tracking system) and provides reliable information on remaining fuel volume, fuel tank fill-up and draining volumes and helps fleets to set up clear fuel accounting and prevent fuel theft from vehicle’s tank. Wireless fuel level sensor is also used for fuel level monitoring in stationary tanks.

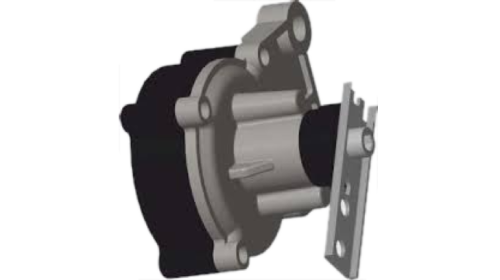

Axle Load Sensor

Axle load sensor for leaf spring suspension.

Position sensor is used in transport telematics systems to monitor axle loads, determine the axle load in vehicles with spring suspension, prevent exceeding axle loads.

Most Tracked Routes

About Us

Serving customers since 1987

Track your assets anywhere in the world.

Record their hours of service each day.

Log the route each asset takes.

Send SMS text to operators worldwide.

ELD keeps drivers compliant

Driver medical records

Pre-Trip inspection forms

Fleet manager maps with filters

IFTA fuel receipts and form

Customize reporting period for each trailer

Record trailer drops and pickups

World-wide tracking coverage

Solar powered

800-972-3027

800-972-3027